Isomerization (Axens Process Licensing)

HIGH OCTANE C5/C6 CUTS VIA ISOMERIZATION PROCESSES

MEET MARKET DEMANDS WITH HIGH OCTANE ISOMERIZATION PROCESSES

From once-through to advanced recycle isomerization processes, we offer the complete line of isomerization solutions that, by increasing C5/C6 naphtha cut octane numbers up to 92, go far to meet tighter gasoline pool specifications. The isomerate product is free of sulfur, aromatics and olefins, making it an excellent gasoline pool component. Isomerization fits well with the trend to remove benzene precursors from reformer feedstock, and possible co-processing of light reformate fractions can resolve benzene content constraints. The question of which process to select will depend on a number of criteria such as feed composition and desired octane number. We have achieved a significant market penetration since the 90’s through the implementation of innovative process schemes combined with state-ofthe-art chlorinated alumina catalysts.

CHLORINATED ALUMINA CATALYSTS

Chlorinated alumina is the best catalyst to meet the need for today’s high octane requirements. Its high activity permits operation at the lower reactor temperatures that enable higher product RON and favor superior yields. The use of molecular sieve adsorbents on the feed and hydrogen make-up streams ensures the removal of feed contaminants and long catalyst lifetimes. Chlorinated alumina-based catalysts are also ideal for retrofitting idle units such as reformers or hydrotreaters with implementation of feed pretreatment and off-gas neutralization packages. The substantial octane gain and reduced catalyst cost account for the short pay-back time, usually less than a year.

Our isomerization technologies employ ATIS-2L catalyst which provides an unsurpassed combination of high activity low cost and low platinum content.

ONCE-THROUGH C5/C6 ISOMERIZATION: LOWEST INVESTMENT COST

This least-cost path to moderate octane gain can provide, in some cases, a sufficient boost to the gasoline pool octane. Typically, the octane for a feed having a C5 to C6 ratio of 40:60 will have an increase in RON from 70 to 83-84 after isomerization. We employ a permutable reactor design; that is, either reactor can be used in the lead or lag position or it can be operated independently during catalyst servicing. This assures ultra-high on-stream service.

OCTANE ENHANCEMENT WITH DEISOPENTANIZER (DIP) OR DEISOHEXANIZER (DIH)

The maximum octane number available from a oncethrough system is limited by the thermodynamic equilibrium of the C5/C6 mixture. Distillation is one way to achieve octane improvement by either allowing isomers to bypass the reactor (DIP) or by recycling normal paraffins to the reactor (DIH, shown hereafter). However, these approaches still leave normal paraffins in the product.

ADVANCED RECYCLE: IPSORB™

Ipsorb is the most economic path available to convert all normal paraffins to their iso-paraffins. A vapor phase mole sieve section is used to adsorb normal paraffins for recycle to the reactor.

ULTIMATE OCTANE: HEXORB™

The Hexorb process also completely adsorbs and converts all normal paraffins to isomers. The difference is that methyl pentanes (RON 74) are also converted, affording the highest possible octane for a C5-C6 feed (up to RON 92).

FOR BETTER BOTTOM LINE RESULTS

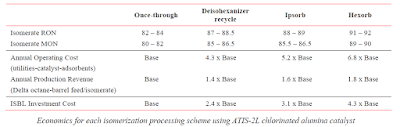

Our isomerization technologies are ready to help meet a refinery's octane objectives, whether it is for a new unit or debottlenecking and revamping of oncethrough and deisohexanizer units. Relative differences between the isomerization schemes with regard to investment cost, operating cost and product revenue, are shown in the table below. Our isomerization technologies are also well suited for stepwise installation of octane improvement projects. Typical payout times are on the order of a year.

COMMERCIAL EXPERIENCE

We entered the C5-C6 isomerization field late, in the 90’s, with a powerful R&D support at both lab and pilot scale sizes. Nevertheless, more than 50 isomerization units have been licensed by Axens, and since the marketing of ATIS-2L catalyst in 2003, more than 30 new units have been designed.

Tidak ada komentar untuk "Isomerization (Axens Process Licensing)"

Posting Komentar